Design Specific specialises in creating a wide range of specialist medical devices […]

Continue Reading- All

Category Archives

Colour

-

Embracing the Warmth of “Peach Fuzz” – Pantone Colour of the Year 2024 with Chieftain Fabrics

by chieftainfabrics on

Embracing the Warmth of “Peach Fuzz” – Pantone Colour of the Year 2024 with Chieftain Fabrics

by chieftainfabrics onExplore the enchanting world of “Peach Fuzz” with Chieftain Fabrics, and transform […]

Continue Reading -

Riding in Style: The Restoration of Paul McCartney’s 1972 Wings Tour Bus

by chieftainfabrics on

Riding in Style: The Restoration of Paul McCartney’s 1972 Wings Tour Bus

by chieftainfabrics onIn the Summer of ’72, The Summer Of Wings Paul McCartney chose […]

Continue Reading -

Using Fabric Inspired by the Pantone Colour of the Year 2023, ‘Viva Magenta 18’

by chieftainfabrics on

Using Fabric Inspired by the Pantone Colour of the Year 2023, ‘Viva Magenta 18’

by chieftainfabrics onIncorporating “Viva Magenta 18” – Pantone Colour of the Year 2023, into Your […]

Continue Reading -

Chieftain Fabrics new Crib 7 range ‘Protect-7’

by chieftainfabrics on

Chieftain Fabrics new Crib 7 range ‘Protect-7’

by chieftainfabrics onWhat does Crib 7 mean? The Crib 7 certification has its […]

Continue Reading -

Christmas Colours – Enjoy the Magic All Year Round

by chieftainfabrics on

Christmas Colours – Enjoy the Magic All Year Round

by chieftainfabrics onThe most wonderful time of the year, Christmas is truly upon us. […]

Continue Reading -

Chieftain Fabrics new range ‘Earthly’

by chieftainfabrics on

Chieftain Fabrics new range ‘Earthly’

by chieftainfabrics onChieftain Fabrics are delighted to share with you our new range ‘Earthly’. […]

Continue Reading -

Product information: Chieftain MultiStretch

by Chieftain Fabrics on

Product information: Chieftain MultiStretch

by Chieftain Fabrics onPerformance fabric – Chieftain MultiStretch Rosemary At Chieftain our passion is […]

Continue Reading -

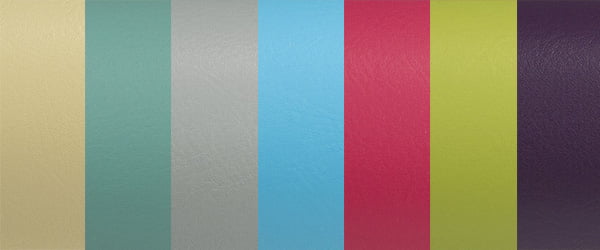

Chieftain Vinyl Colour Ideas

by Chieftain Fabrics on

Chieftain Vinyl Colour Ideas

by Chieftain Fabrics onA question we often get asked at Chieftain Fabrics is what colour […]

Continue Reading -

The Good and the Bad Vinyl Fabrics

by Chieftain Fabrics on

The Good and the Bad Vinyl Fabrics

by Chieftain Fabrics onA known idiom reminds us not to be ‘penny wise, pound […]

Continue Reading