Design Specific specialises in creating a wide range of specialist medical devices […]

Continue Reading- All

Category Archives

Technology

-

Chieftain Fabrics new Crib 7 range ‘Protect-7’

by chieftainfabrics on

Chieftain Fabrics new Crib 7 range ‘Protect-7’

by chieftainfabrics onWhat does Crib 7 mean? The Crib 7 certification has its […]

Continue Reading -

Product information: Chieftain MultiStretch

by Chieftain Fabrics on

Product information: Chieftain MultiStretch

by Chieftain Fabrics onPerformance fabric – Chieftain MultiStretch Rosemary At Chieftain our passion is […]

Continue Reading -

Fabric Technology Changes

by Chieftain Fabrics on

Fabric Technology Changes

by Chieftain Fabrics onSince coated fabrics such as vinyl were invented in the early 1900’s, the industry […]

Continue Reading -

The Good and the Bad Vinyl Fabrics

by Chieftain Fabrics on

The Good and the Bad Vinyl Fabrics

by Chieftain Fabrics onA known idiom reminds us not to be ‘penny wise, pound […]

Continue Reading -

OVS Via Dante – experiential retail store for the 21st century customer

by Chieftain Fabrics on

OVS Via Dante – experiential retail store for the 21st century customer

by Chieftain Fabrics onA recent study of the European e-commerce industry conducted by RetailMeNot and the Centre […]

Continue Reading -

Can we avoid Phthalates?

by Chieftain Fabrics on

Can we avoid Phthalates?

by Chieftain Fabrics onWhat are Phthalates? Phthalates are a group of chemical compounds used in […]

Continue Reading -

The history of vinyl fabric

by Chieftain Fabrics on

The history of vinyl fabric

by Chieftain Fabrics onAccounts of plastic and rubber stretch back to discoveries by Columbus in […]

Continue Reading -

‘The School on the Terraces’ sets an example for how the school of the future should look

by Chieftain Fabrics on

‘The School on the Terraces’ sets an example for how the school of the future should look

by Chieftain Fabrics on2016 will see the completion of a new primary school in the […]

Continue Reading -

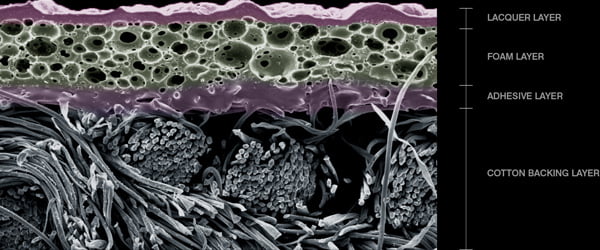

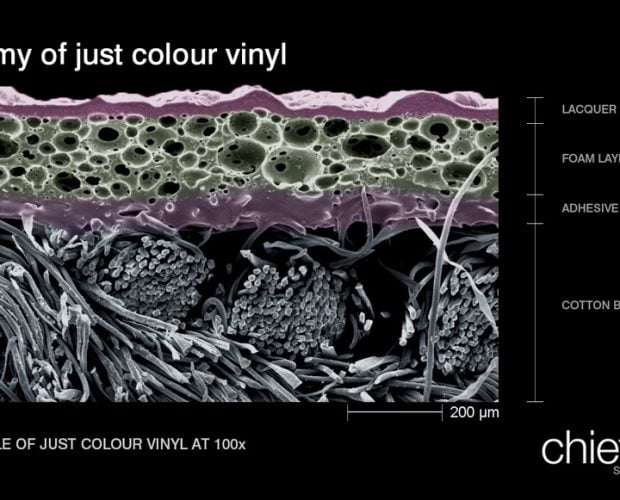

Anatomy of our contract grade vinyl fabric

by Chieftain Fabrics on

Anatomy of our contract grade vinyl fabric

by Chieftain Fabrics onElectron microscopes are used to investigate the ultrastructure of a wide range […]

Continue Reading