Recently, Design Insider noted that a smooth specification process can help ensure […]

Continue Reading- All

Category Archives

Misc

-

Do low prices = poor quality?

by Chieftain Fabrics on

Do low prices = poor quality?

by Chieftain Fabrics onBenjamin Franklin said that “the bitterness of poor quality remains long after […]

Continue Reading -

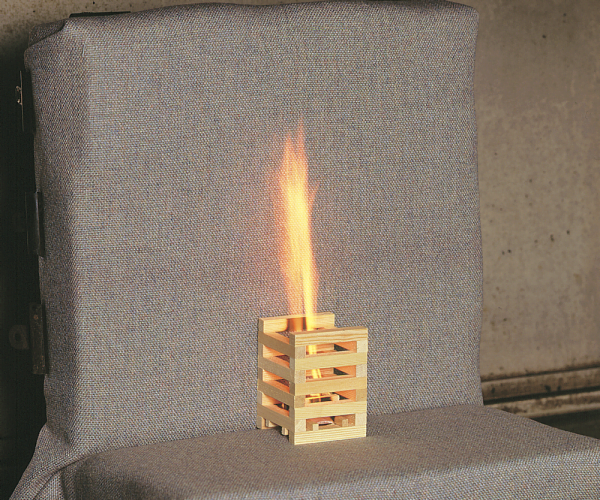

Crib Test Explained

by Chieftain Fabrics on

Crib Test Explained

by Chieftain Fabrics onBritish Standards are the standards produced by BSI Group which ‘Set up […]

Continue Reading -

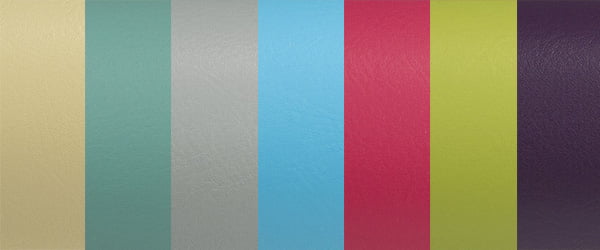

The Good and the Bad Vinyl Fabrics

by Chieftain Fabrics on

The Good and the Bad Vinyl Fabrics

by Chieftain Fabrics onA known idiom reminds us not to be ‘penny wise, pound […]

Continue Reading -

Can we avoid Phthalates?

by Chieftain Fabrics on

Can we avoid Phthalates?

by Chieftain Fabrics onWhat are Phthalates? Phthalates are a group of chemical compounds used in […]

Continue Reading -

What happens to your project if your supplier runs out of stock?

by Chieftain Fabrics on

What happens to your project if your supplier runs out of stock?

by Chieftain Fabrics onPoor risk management can have serious knock on effects on your project. […]

Continue Reading -

The history of vinyl fabric

by Chieftain Fabrics on

The history of vinyl fabric

by Chieftain Fabrics onAccounts of plastic and rubber stretch back to discoveries by Columbus in […]

Continue Reading -

Impact of REACH on the upholstery industry

by Chieftain Fabrics on

Impact of REACH on the upholstery industry

by Chieftain Fabrics onWhat is REACH? REACH is ‘a regulation of the European Union, adopted […]

Continue Reading -

‘The School on the Terraces’ sets an example for how the school of the future should look

by Chieftain Fabrics on

‘The School on the Terraces’ sets an example for how the school of the future should look

by Chieftain Fabrics on2016 will see the completion of a new primary school in the […]

Continue Reading -

How The Royal London Hospital used design to be less intimidating

by Chieftain Fabrics on

How The Royal London Hospital used design to be less intimidating

by Chieftain Fabrics onThe Royal London Hospital is one of six hospitals owned and managed […]

Continue Reading